For small design shops and large corporations, no-muss, no-fuss Autodesk PLM 360 is a sophisticated, cloud-based PLM system available to “anyone, anytime, anywhereâ€â€”and inexpensively.

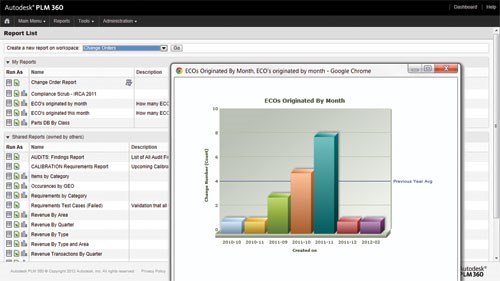

PLM is nothing without reporting capabilities. Here, the bar chart shows the number of ECOs created per month—on top of a line showing the previous year’s monthly average for ECO creation.

Previous

Next

Related:

Digital Domain

Related Suppliers

-

Autodesk, Inc.

Want product lifecycle management (PLM)—but not the hassle of implementation consultants, information technology maintenance, complicated licensing and pricing, and jumping through hoops to add users? Check out Autodesk PLM 360 from Autodesk, Inc. (Lake Oswego, OR; autodeskplm360.com). Without cracking a smile, Brenda Discher, Autodesk’s vice president of marketing, claims this new enterprise PLM system “is built on the cloud from the ground up.â€

Â

Behind the cloudy buzzwords

Â

“Traditional PLM systems have historically been expensive, complicated, and engineering-centric,†says Discher. PLM 360 is none of these. Part of the reason is because it’s cloud-based. Cloud technology, continues Discher, has over time become real, apparent, and workable. The technology also pretty much negates the upfront and ongoing costs in capital expenditures so common with conventional enterprise software systems.

Cloud tech invokes a bunch of buzz-words: “software as a service,†“always online,†“ instant updates,†“zero deployment,†and “scalable,†for starters. Translated, this all means PLM 360 is always “on,†current, and, as Discher says, available to “anyone, anytime, anywhere.†There’s no hardware or data network to install; none of that tedious, daunting installation and configuration that goes with installing conventional software (especially enterprise management systems). PLM access is through a web browser on any desktop or mobile device. And everyone uses the same version of PLM software.

New users can be easily added at a fraction of the cost for comparable PLM systems. Go online, fill out a form, pay your dues, and go. Using all the system’s functions is free for the first three users (including an administrator), then $75 per user thereafter. To just view stuff in the PLM system or to have limited workflow participation, such as approving an engineering change order, the system costs $25/user/month. Subscription fees are based on an annual contract; there are no startup or operational costs (such as process consultants and programmers). Users are “up and running in minutes, rather than months,†says Stephen Bodnar, Autodesk’s vice president of Data Management and PLM.

Autodesk describes PLM 360 as being a secure, multi-tenant PLM system. This means corporate customers have their password-protected instance of PLM 360, which is exclusive to people within that company. Customer’s data is completely separate; it’s never commingled—neither in the database nor the memory pools.

Â

Cloud vs. departmental product management

Autodesk PLM 360 is geared for the people who are actually more interested in using PLM rather than those who are keen on installation and configuration. The system is “insanely configurable,†says Discher. Its modern, “no-programming†interface lets users map out business processes and customize reports by pointing, clicking, and drag-and-dropping schematics, files, layouts, and the like.

To help customers setup the system, PLM 360 comes with 140 preconfigured, industry-standard PLM applications “out of the box.†(That’s another inside joke: There is no “box†in the cloud.) Customers can modify these applications as they see fit to jumpstart and fold PLM into their operations. Customers can add custom business process logic and modify data types and attributes, or create new applications. The preconfigured applications include program and project management, new product introduction, change management, costing, bills of materials, quality processes, supplier management and sourcing, request for quote, and even equipment calibration.

PLM 360 plays nicely with Vault, Autodesk’s on-premise product data management (PDM) system. “Cloud is the perfect tech for PLM. It is not the perfect tech for PDM,†explains Robert “Buzz†Kross, Autodesk senior vice president of Design, Lifecycle & Simulation Group, for engineering data management. Here’s why. Engineering departments are engineering-centric. They sling around big files representing the big problems that engineering departments solve. These files, and related intellectual property (IP), generally need to stay inside a company’s firewall. PDM is perfect for that. But when the IP needs to be shared across a distributed network of managers, engineers of all stripes, suppliers, and even customers outside the enterprise, PLM is the way to go. PLM is much better at managing these data. It is also optimized for turning design data into “light-weight†product information—light weight in file size.

Kross is quick to point out that “Vault is not our on-premise version of PLM.†In fact, customers do not even need Vault to use PLM 360. That said, application programming interfaces in PLM 360 support bidirectional data communications between it and third-party PDM systems. And more: PLM 360 can be integrated with materials requirements planning, enterprise resource planning, and pretty much anything else under the PLM umbrella, including systems behind corporate firewalls.